Description

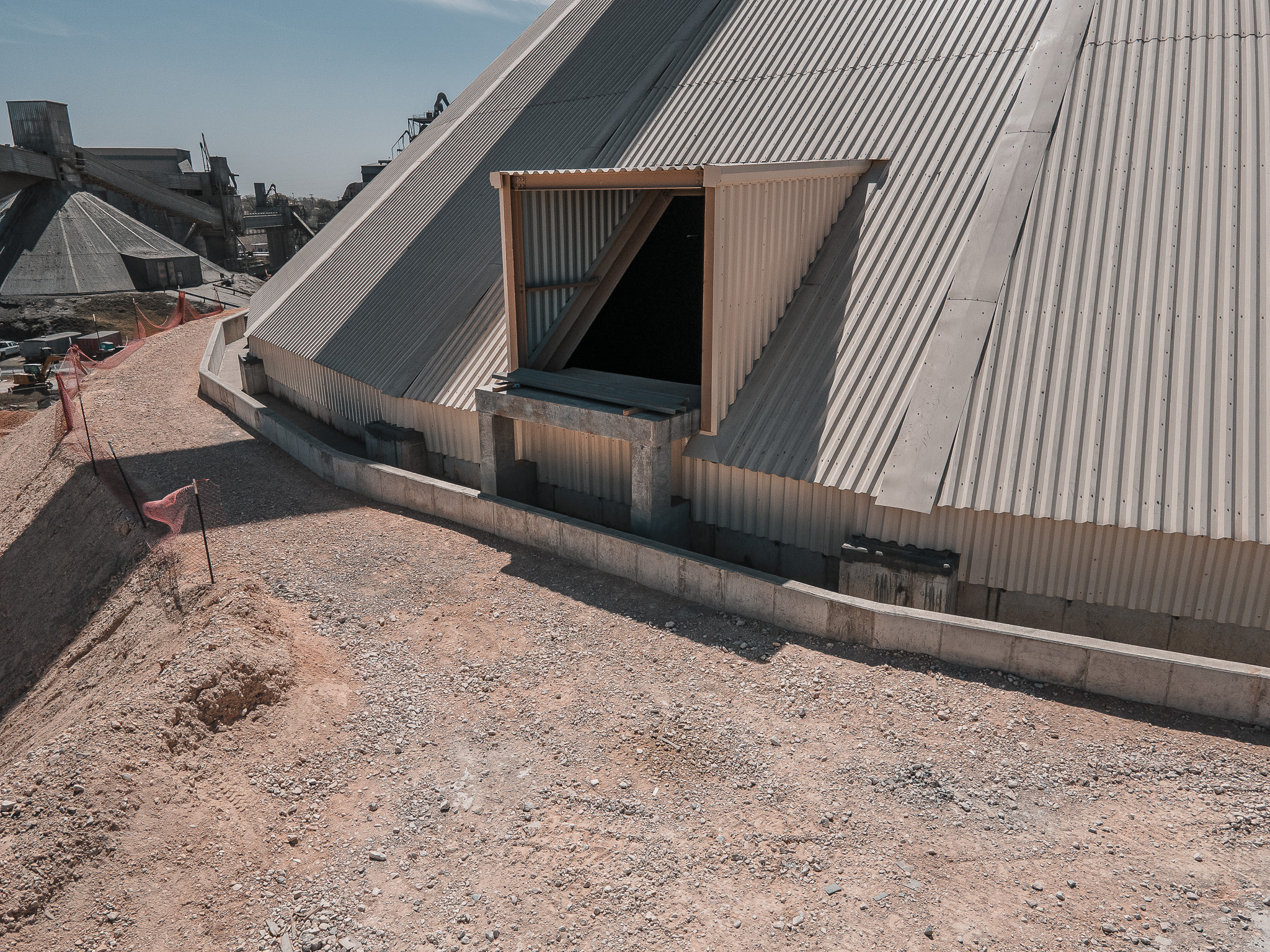

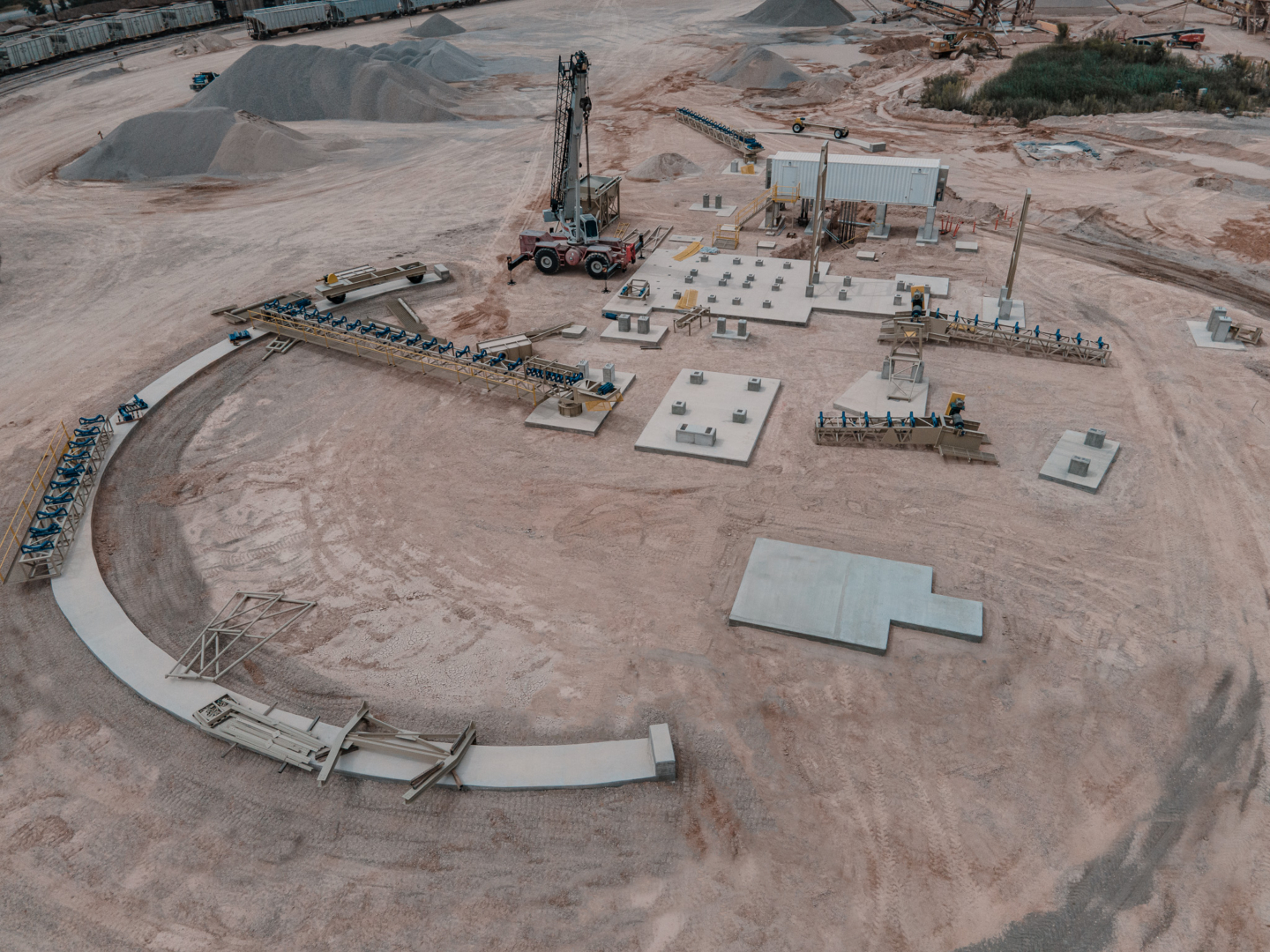

The construction of this clinker dome replicates the design and functionality of the neighboring structure while enhancing the facility’s material stockpiling capabilities. The project scope included building conveyor pedestals, structural walls, 35-foot drilled piers to support an overhead conveyor, and concrete work for electrical infrastructure.

Wall construction proved to be one of the most demanding phases of the project. Crews poured each section and manually repositioned all MEVA lite forms due to the confined workspace and restricted access, which was limited to a single ramp. Transporting materials was challenging and required strategic planning by the superintendent to relocate rebar and supplies while maintaining productivity despite the site constraints.

Throughout the project, the superintendent collaborated closely with the client and engineers, using a total station to establish accurate reference points, identify potential errors, and aid in understanding steel placement. Precision, expertise, and collaboration defined the project, with the Superior team working tirelessly to ensure the highest standards of quality and safety were met at every stage.